ASTM D1566 Standard Terminology Relating to Rubber

ASTM D1566, titled “Standard Terminology Relating to Rubber,” is a foundational standard in the rubber industry that provides precise and consistent definitions of terms used in rubber manufacturing, testing, and engineering. It serves as a common language for industry professionals, ensuring clarity and avoiding miscommunication in technical and commercial contexts.

This terminology standard is critical for diverse sectors, including automotive, aerospace, consumer products, and industrial applications. By standardizing the vocabulary, ASTM D1566 supports efficient collaboration, quality assurance, and compliance with international standards.

Purpose of ASTM D1566

The primary purpose of ASTM D1566 is to establish standardized definitions for terms specific to rubber materials and their properties. This ensures that engineers, scientists, manufacturers, and regulatory bodies operate with a shared understanding.

Key objectives include:

- Enhancing communication among professionals in the rubber industry.

- Supporting accurate product specifications and documentation.

- Facilitating international trade by aligning terminology across borders.

Key Concepts in ASTM D1566

ASTM D1566 covers essential concepts related to rubber, including:

- Material Definitions:

- Natural Rubber (NR)

- Synthetic Rubber (e.g., SBR, NBR, EPDM)

- Elastomers

- Property Descriptions:

- Hardness

- Tensile Strength

- Resilience

- Process Terms:

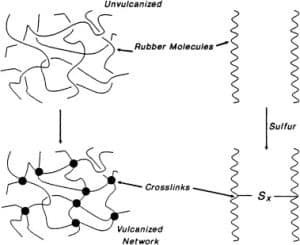

- Vulcanization

- Compounding

- Aging

These terms are vital for understanding the behavior and performance of rubber materials under various conditions.

Scope of ASTM D1566

The scope of ASTM D1566 extends to all aspects of the rubber industry, from raw materials to finished products. It includes:

- Natural and Synthetic Rubbers: Definitions for commonly used types.

- Manufacturing Processes: Terms describing production techniques like vulcanization and molding.

- Performance Properties: Descriptions of characteristics such as elasticity, compression set, and abrasion resistance.

ASTM D1566 is widely used in industries where rubber plays a critical role, such as automotive manufacturing, medical devices, and industrial seals.

Key Definitions in ASTM D1566

Some of the most critical terms defined in ASTM D1566 include:

- Vulcanization: A chemical process for enhancing the strength, elasticity, and durability of rubber.

- Resilience: The ability of rubber to return to its original shape after deformation.

- Hardness: The resistance of rubber to indentation, typically measured using the Shore scale.

- Aging: The changes in physical properties of rubber due to environmental factors like heat and oxygen.

These definitions provide clarity, especially when comparing materials or designing rubber products for specific applications.

Importance of Standardized Terminology

Standardized terminology in ASTM D1566 is crucial for:

- Avoiding Miscommunication:

- Ensures consistent understanding across teams, suppliers, and customers.

- Reduces errors in product design and testing.

- Enhancing Collaboration:

- Promotes seamless collaboration between manufacturers and end-users.

- Facilitates knowledge sharing in research and development.

- Supporting International Trade:

- Aligns with global standards, enabling smoother cross-border transactions.

Applications of ASTM D1566

ASTM D1566 terminology is applied in various ways:

- Product Development:

- Describing material requirements and performance criteria.

- Quality Control:

- Ensuring consistency in manufacturing processes.

- Regulatory Compliance:

- Meeting industry and governmental standards for product safety and performance.

Comparison with Other Standards

While ASTM D1566 focuses on the United States rubber industry, it aligns closely with other international standards, such as:

- ISO Terminology for Rubber: A global counterpart providing similar definitions.

- DIN Standards: German standards used in European markets.

ASTM D1566 often complements these standards, ensuring compatibility across regions.

Challenges in Rubber Terminology

Despite its benefits, implementing ASTM D1566 can present challenges:

- Evolving Definitions: As materials and technologies advance, terms must be updated to remain relevant.

- Misinterpretation Risks: Variability in how terms are understood across regions or industries.

- Maintaining Consistency: Ensuring adherence to terminology across all levels of an organization.

Use of ASTM D1566 in Quality Assurance

In quality assurance, ASTM D1566 provides a framework for:

- Ensuring Product Specifications: Clear definitions help meet exact material and performance criteria.

- Consistency in Descriptions: Standard terms prevent discrepancies between batches or suppliers.

Role in Education and Research

ASTM D1566 is a valuable resource for:

- Academic Programs: Teaching the principles of rubber science and engineering.

- Research Studies: Providing a standardized vocabulary for documenting findings.

Case Studies Using ASTM D1566

- Automotive Applications:

- Improved communication between manufacturers and suppliers regarding material requirements.

- Result: Reduced defects in rubber components.

- Industrial Seals:

- Standardized definitions of resilience and compression set.

- Result: Enhanced product reliability.

FAQs About ASTM D1566

- What is ASTM D1566?

It is a standard terminology for defining terms related to rubber materials and processes. - Why is it important?

It ensures consistent communication and accurate product specifications in the rubber industry. - What industries use ASTM D1566?

Automotive, aerospace, consumer goods, and industrial manufacturing. - Does ASTM D1566 cover synthetic rubbers?

Yes, it includes definitions for synthetic rubbers like EPDM and NBR. - How does it support international trade?

By aligning terminology, it simplifies cross-border collaboration and compliance. - Is ASTM D1566 used in education?

Yes, it is a key resource for academic and research programs in rubber science.