ASTM D3183 Standard Practice for Rubber—Preparation of Pieces for Test Purposes from Products

ASTM D3183 is a critical standard practice in the rubber industry, outlining procedures for preparing test pieces from rubber products to ensure consistency and reliability in material testing. Proper sample preparation is essential for obtaining accurate and reproducible test results, as variations in sample handling can significantly influence outcomes.

This standard is widely used across industries like automotive, aerospace, construction, and consumer goods, where rubber materials are integral to product performance and safety.

Scope of ASTM D3183

The scope of ASTM D3183 includes:

- Rubber Products: Items such as tires, seals, gaskets, and molded parts.

- Sample Types: Preparation of small pieces for tensile, compression, and other mechanical tests.

- Test Purposes: Ensuring prepared samples meet standard dimensions and quality requirements for testing.

The practice applies to a variety of products and industries where precise rubber testing is required for material validation and quality control.

Purpose of ASTM D3183

The primary purpose of ASTM D3183 is to standardize the preparation of test pieces from finished rubber products, which ensures:

- Sample Uniformity: Eliminating variability caused by inconsistent preparation methods.

- Testing Reliability: Supporting accurate and reproducible test results.

- Industry Compliance: Meeting regulatory and industry-specific standards for product evaluation.

Key Concepts in ASTM D3183

ASTM D3183 emphasizes:

- Sample Preparation: Techniques for cutting, shaping, and conditioning samples to meet specific test requirements.

- Precision in Testing: Maintaining strict control over sample dimensions and surface quality.

- Rubber Product Evaluation: Preparing pieces that accurately represent the material’s properties.

Preparation of Test Pieces

The preparation of test pieces involves several steps:

- Selection of Test Samples: Identifying representative sections of the product that reflect its overall properties.

- Cutting and Shaping: Using appropriate tools to cut samples to the required dimensions.

- Avoiding Defects: Ensuring samples are free from surface defects, contamination, or imperfections that could affect test results.

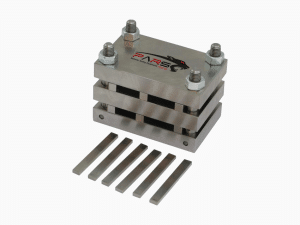

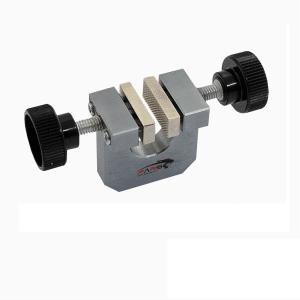

Equipment Used in ASTM D3183

Standard equipment required for ASTM D3183 includes:

- Cutting Tools: Such as die cutters, rotary blades, or precision saws for clean sample preparation.

- Conditioning Equipment: To maintain environmental consistency during preparation.

- Standardized Templates: Ensuring uniform dimensions across all samples.

Proper equipment calibration and maintenance are essential for achieving consistent results.

Factors Influencing Test Results

Several factors can affect the accuracy and reliability of test results:

- Surface Defects: Imperfections on the sample surface can lead to inaccurate readings.

- Dimensional Accuracy: Variations in sample size can skew test outcomes.

- Environmental Conditions: Temperature and humidity during preparation can impact the rubber’s properties.

Applications of ASTM D3183

ASTM D3183 plays a vital role in:

- Material Characterization: Providing insights into the mechanical properties of rubber materials.

- Product Development: Supporting the design and optimization of new rubber products.

- Quality Control: Ensuring products meet performance and safety standards.

Comparison with Other Standards

ASTM D3183 complements other standards, such as:

- ASTM D3182: Focuses on preparing rubber compounds, while ASTM D3183 addresses test pieces from finished products.

- ASTM D412: For tensile testing of rubber samples, which often rely on pieces prepared under ASTM D3183.

These standards work together to ensure comprehensive rubber testing and evaluation.

Common Challenges and Solutions

Challenges in implementing ASTM D3183 include:

- Maintaining Sample Consistency: Variability in preparation can lead to inconsistent results. Solution: Use calibrated tools and follow strict procedures.

- Operator Skill: Human error during preparation can affect accuracy. Solution: Train personnel in standard methods.

- Equipment Calibration: Misaligned or worn equipment can introduce defects. Solution: Regular calibration and maintenance.

Case Studies Using ASTM D3183

- Automotive Components:

- Ensured consistent testing of rubber seals, leading to improved performance and durability.

- Result: Enhanced reliability of critical automotive systems.

- Industrial Applications:

- Optimized the preparation of samples for conveyor belt testing.

- Result: Identified material improvements that increased belt lifespan.