ASTM D395 Standard Test Methods for Rubber Property—Compression Set

ASTM D395 is a widely recognized standard for evaluating the compression set of rubber materials, which measures a material’s ability to return to its original thickness after being compressed under a specified load and time. This test is critical for determining how well a rubber product can maintain its sealing or cushioning properties in real-world applications.

Industries such as automotive, construction, and industrial manufacturing rely on ASTM D395 to validate the performance and durability of rubber components like seals, gaskets, and vibration isolators.

Scope of ASTM D395

ASTM D395 applies to:

- Materials Covered: Natural and synthetic rubbers, elastomers.

- Applications: Testing components such as O-rings, gaskets, and other compressible products.

- Testing Conditions: Simulates real-world scenarios with specified loads and environmental conditions.

This standard ensures that rubber materials can endure compression forces without significant deformation over time.

Purpose of ASTM D395

The primary purpose of ASTM D395 is to:

- Measure Compression Set: Determine how much permanent deformation occurs after a material is compressed and then released.

- Evaluate Durability: Assess whether rubber materials can maintain their intended function over time.

- Support Material Development: Provide data for improving formulations and designs.

Key Concepts in ASTM D395

- Compression Set: The percentage of permanent deformation remaining after a compressive load is removed.

- Recovery: The material’s ability to return to its original thickness.

- Load Relaxation: Reduction in compressive stress over time.

- Permanent Deformation: A critical measure of material failure in sealing applications.

Types of ASTM D395 Methods

ASTM D395 includes two methods for testing:

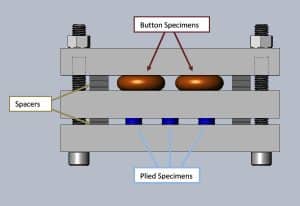

- Method A (Plates):

- Samples are compressed between rigid plates.

- Suitable for general rubber materials.

- Method B (Disks):

- Samples are compressed using a cylindrical fixture.

- Commonly used for O-rings and seals.

The choice of method depends on the material’s intended application and testing requirements.

Equipment Used in ASTM D395 Testing

Testing requires precise equipment, including:

- Compression Fixtures: Apply controlled compressive forces to the sample.

- Measurement Devices: Calipers or micrometers for assessing dimensional changes.

- Environmental Chambers: Control temperature and humidity during testing.

Proper calibration of equipment is essential for obtaining accurate and repeatable results.

Test Procedure for ASTM D395

The ASTM D395 test involves these steps:

- Sample Preparation:

- Cut specimens to the specified dimensions using a standardized die.

- Condition samples to ensure uniformity.

- Compression Testing:

- Place the specimen in a compression fixture.

- Apply a constant compressive force for the specified duration, typically at elevated temperatures.

- Measurement After Recovery:

- After the compression period, release the load and allow the sample to recover for a specified time.

- Measure the final thickness to calculate the compression set.

Parameters Evaluated in ASTM D395

- Percentage Compression Set:

Compression Set (%) = ((Original Thickness - Recovered Thickness) / Original Thickness) × 100 - Dimensional Recovery: Indicates the material’s ability to regain its shape.

- Stress Retention: The ability to maintain compressive force over time.

Factors Affecting Test Results

Several factors can influence the outcomes of ASTM D395 tests:

- Material Quality: Variations in rubber formulations can impact performance.

- Environmental Conditions: Temperature and humidity during testing can alter results.

- Compression Time: Longer compression times may lead to higher permanent deformation.

Applications of ASTM D395

ASTM D395 is crucial for:

- Seals and Gaskets: Ensuring long-term sealing performance under compression.

- Vibration Dampeners: Evaluating durability in applications requiring elastic recovery.

- Automotive Components: Testing engine mounts and suspension bushings for reliability.

Comparison with Other Standards

ASTM D395 complements other standards, such as:

- ISO 815: A similar international standard for determining compression set.

- ASTM D412: Measures tensile properties, providing additional insights into material performance.

Common Challenges and Solutions

- Maintaining Consistent Loading:

- Solution: Use calibrated fixtures to apply even compression.

- Accurate Measurement:

- Solution: Use high-precision tools and follow standard procedures.

- Environmental Control:

- Solution: Conduct tests in controlled temperature and humidity conditions.

Case Studies Using ASTM D395

- Automotive Applications:

- Tested engine gaskets for long-term compression set.

- Result: Enhanced material selection, improving engine sealing performance.

- Industrial Seals:

- Evaluated O-rings used in high-pressure environments.

- Result: Improved reliability, reducing downtime in industrial systems.